1830

Construction

The building of the windmill, the tallest in Buckinghamshire, started in 1830 to the order of Mr James Anstiss. The bricks for the 65 ft tower were burnt in a kiln set up near the mill, the clay being dug from a depression about 100 yards to the northeast. Two of the bricks are inscribed “JA Hunt 1830” and “G & B 1830”.

1832

Completion

There was a delay in building during the winter of 1830 while Mr Anstiss visited America. A family member believes he did this to earn money to fund the completion of the mill. While he was away, the half-completed tower was thatched to protect the building during adverse weather. William Cooper, millwrights of Aylesbury, installed the machinery during the following twelve months incorporating the latest ideas in millwrighting. The mill was completed in 1832. William Cooper was declared bankrupt shortly afterwards.

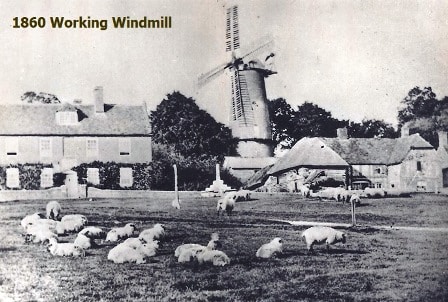

1860

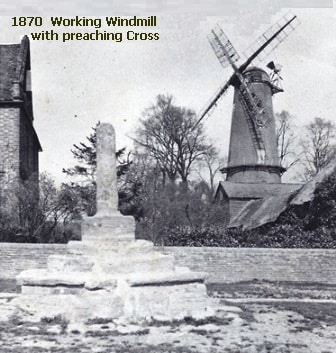

1870

Early life

Early in the mill’s life the first floor was raised and reorganised to allow a 20hp Vertical Steam Engine to be installed on the massive bed-stone on the ground floor, with its boiler in the open outside the north door. The drive from the engine was taken up the mill to engage the great spur wheel. This was a common practice at the time. The engine enabled the mill to work regardless of the wind particularly important for this mill since it was shielded by nearby hills from winds from the north west round to the north east.

Coal for the engine had to be carted ten miles from the nearest railhead at Winslow.

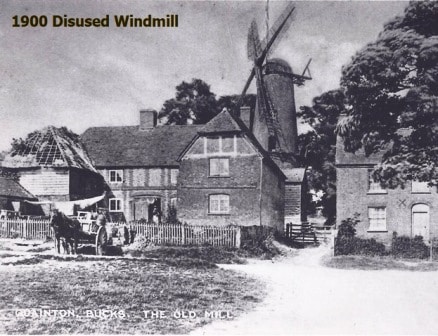

1900

Disuse

It is not known precisely when the mill stopped operating. It was well built and there is no indication that it ever suffered a mechanical breakdown, but in the 1891 census both James and Thomas Anstiss were described as “retired millers”. Stanley Freese, an authority on mills, wrote in 1939 that the mill’s active career came to an end due to:

– the mill’s unfortunate position at the foot of the hill.

– competition from seaport mills.

– the cost and trouble of carting coal from Winslow for the

engine before the through line from London was opened.

– the conversion of the Vale of Aylesbury to grass as a result of

the enclosure of the fields.

Stanley Freese added “whilst wind and steam power were in occasional use some forty years before, the mill ceased to work after the fantail blew off, after which the mill was left derelict”. (The fantail blew off in a gale in 1899.)

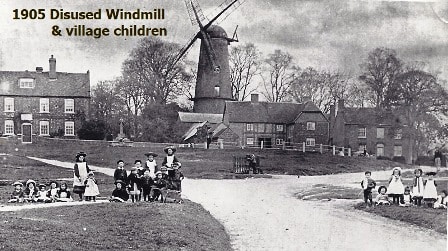

1905

1912

Sale

Although machinery for three pairs of stones was installed, historical records indicate that only two damsels were ever supplied. A damsel is a spindle that helps feed grain into the milling stones. When the mill was put up for sale in 1912 two pairs of stones were listed. It is believed that these two pairs were the only ones serviceable at the time, the third pair having disintegrated and are now on the ground floor. It is recorded that one pair of stones was sold in 1914. It is thought that this was one of the serviceable pairs, leaving the mill, as it is now, with one pair of working stones and one pair in need of restoration.

1914

Purchase

Messrs Prentice of Tring bought the engine and boiler for scrap in 1914.