Oct

Suggestion to Quainton Parish Council that the mill be restored.

1970

Suggestion to Quainton Parish Council that the mill be restored.

1971

Feasibility report written on behalf of the Society for the Preservation of Ancient Buildings and the Department of the Environment.

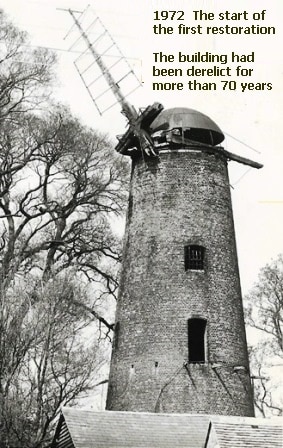

July 1972

Detailed report written on the requirements of a restoration, with costings.

1973

Restoration costed by the National Trust.

1974

Public meeting held to discuss restoration; Quainton Windmill Society formed.

June

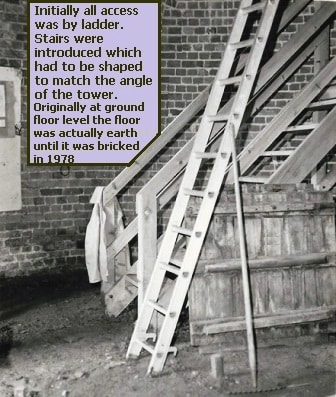

Restoration work started. Ladders erected and temporary flooring installed. Floors cleared and a wall and pit on the ground floor eliminated.

December

Top floor reached; plans made to remove the cap and machinery by crane. The one remaining sail was removed.

1975

Cap and machinery removed.

December

Arrangements made to collect two 35ft pitch pine timbers for the head-frame from St Catherine’s Dock in London. Sufficient boarding for the floors obtained, also 1,000 second hand bricks.

1976

First floor joists of oak and second floor joists of elm in place.

1977

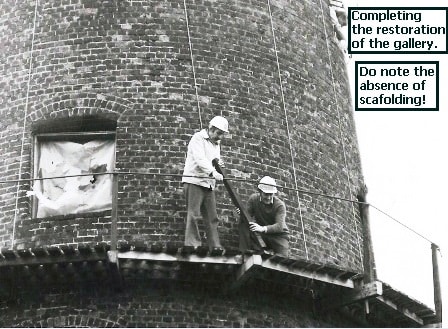

Aylesbury College agreed to make 168 shutters for the sails (because of pressure of work the College could complete only half the task: the Society completed the job using Aylesbury College’s machinery). Brickwork at top of mill re-laid. First and second floors re-boarded. 75% of gallery in place.

1978

Ground floor paved with bricks. Wooden doors fitted to the gallery floor. Electric lighting and power points installed on each floor.

1979

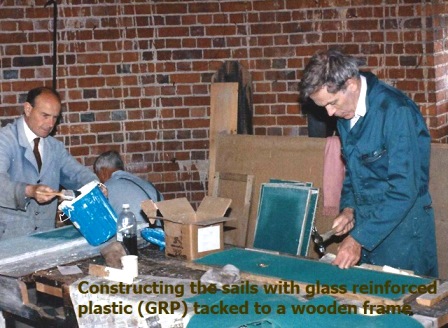

Arrangements made to collect timber for sails from the old Custom House in Cutler Street, London, being demolished by the Port of London Authority: 11 double beams 40 ft long and 24 beams 6ft long collected. Five lengths of iron track from the top of the mill taken away for repair.

1983

Fantail structure completed and head frame assembled.

1986

Head frame, fantail, brakewheel and cap fully assembled on the ground behind the mill.

1987

Cap lifted on to the mill.

1988

Governor completed and installed.

1989

Fantail severely damaged by gales, also fibreglass skirt of the cap torn off. Fantail redesigned, built and refitted; skirt repaired and refitted.

1990

Whips, stocks, and shutters of sails complete and ready for assembly.

1991

Sails assembled.

1992

First of the new sails hoisted into position and fixed.

Oct

All the sails hoisted and fitted into position.

1993

Sails first turned by wind power.

1994

Millstones first turned at operating speed under wind power.

1995

Interior walls of the mill lime-washed white. New floor to Stone Floor fitted.

1997

Grain milled into flour for the first time for about 100 years.

Also

One of the sail hemlaths rotted and broke: several shutters blew out and needed replacing. Grant obtained to build replacement set of sails using modern durable materials. Arrangements made to procure the required timber, galvanized steel, glass fibre sheeting and fixings. New drums for sack hoist fitted.